Anilox and flexographic sleeves

Anilox rolls and sleeves for flexographic printing

At Aufer Iberia, we supply anilox rolls and sleeves for flexography and gravure printing, essential components that ensure the correct transfer of ink between the inking system and the substrate. Anilox cylinders are engraved with ceramic microcells using lasers that precisely control the volume of ink applied, while sleeves (anilox sleeves) offer the advantage of being lightweight, interchangeable, and easy to handle, reducing production downtime.

Thanks to our experience and collaboration with leading manufacturers, we offer our customers tailor-made solutions for every application, from high-definition jobs to large-volume print runs.

Technical characteristics of anilox rolls

- Cell volume (BCM/cm²): determines the amount of ink transferred and is selected based on the type of ink and coverage required.

- Lineature: number of cells per cm or inch, which influences the definition of the design and the uniformity of the inking.

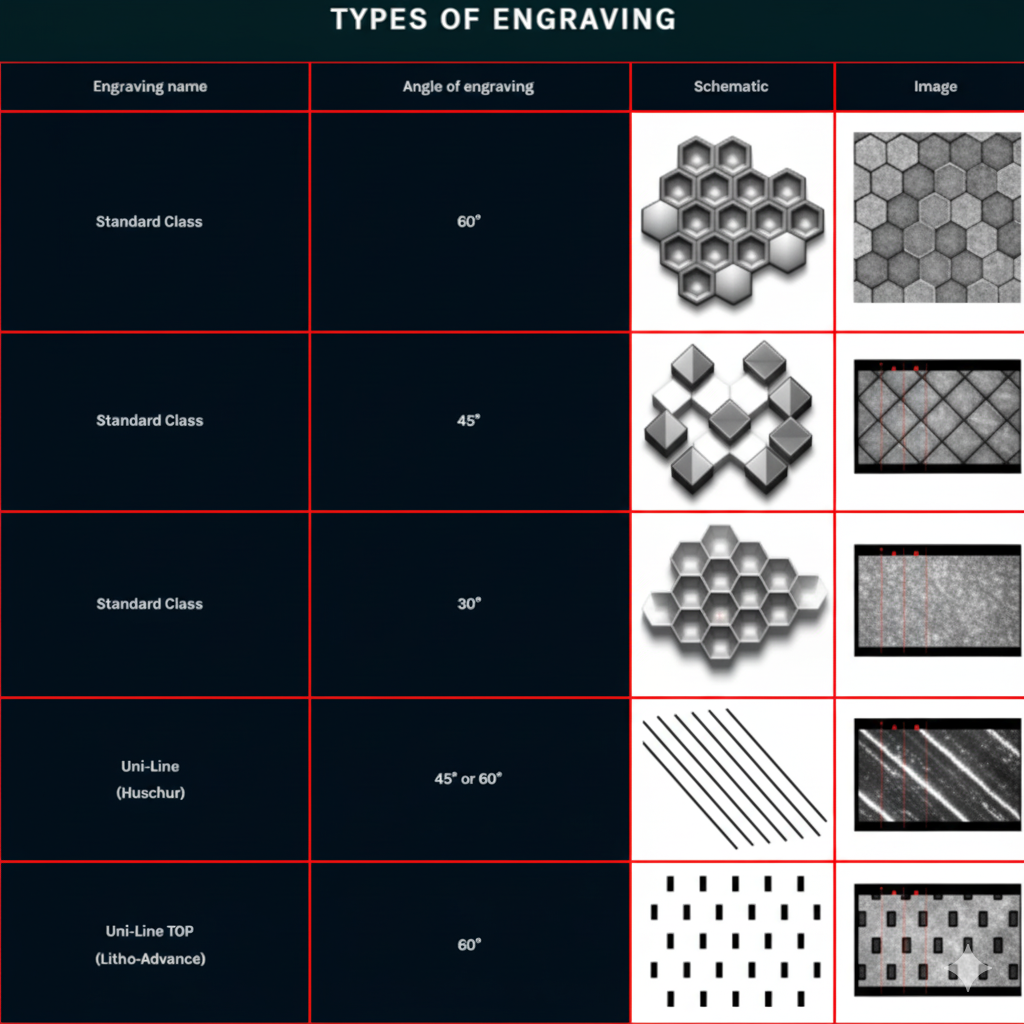

- Cell geometry: hexagonal (60°), open channel, or other variants adapted to the application.

- Laser-engraved ceramic coating: greater durability, wear resistance, and easier cleaning.

Advantages of our anilox rolls and sleeves

- Uniformity in printing

Consistent ink transfer, preventing defects and color variations. - Greater durability

Ceramic coating and precision finishes that extend service life. - Reduced changeover times

Sleeves enable quick exchanges, optimizing productivity. - Compatibility

Solutions adapted to virtually all flexographic machines and systems on the market.

Anilox maintenance and cleaning

Proper maintenance is essential to prevent “cell clogging,” which reduces ink transfer. At Aufer Iberia, we recommend using specific cleaning fluids for anilox rolls that remove residue without damaging the ceramic surface, thus ensuring sharp prints and extending the useful life of the cylinder or sleeve.

Frequently asked questions about anilox rolls and sleeves

What is the difference between an anilox and a sleeve?

The anilox is a complete cylinder, while the sleeve is a lighter, easier-to-handle interchangeable sleeve, ideal for quick job changes.

How to choose the right anilox lineature?

It depends on the type of ink, the desired coverage, and the detail of the design. A high lineature is used for fine, detailed printing, while low lineatures allow for greater ink deposit.

What care do anilox rolls require?

It is essential to clean them regularly with specialized products, avoid hitting the ceramic surface, and use appropriate scrapers so as not to scratch the cells.

Are Aufer Iberia anilox rolls and sleeves compatible with any machine?

Yes, we offer solutions tailored to most manufacturers and flexographic and gravure printing systems on the market.