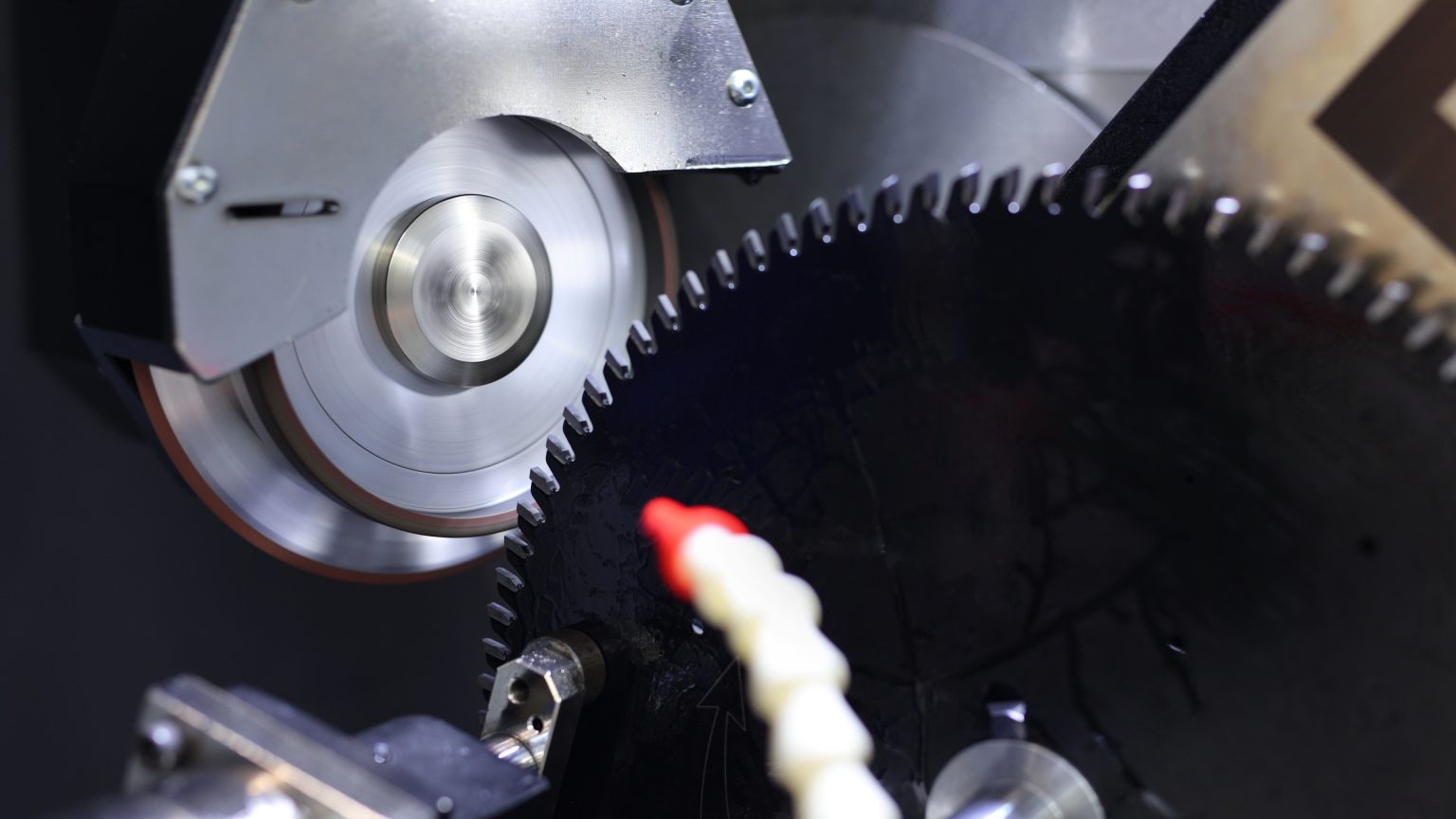

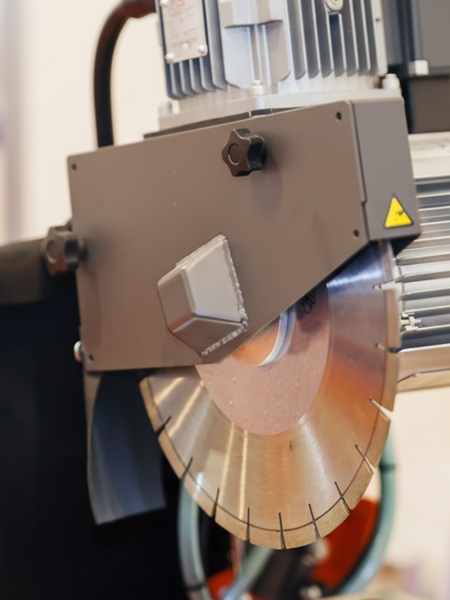

Cutting blades

High-quality cutting blades for industrial processes

At Aufer Iberia, we supply slitting knives for rewinding and converting flexible materials. Our industrial knives are designed to deliver a clean, precise, and long-lasting cut, adapting to different machines and applications in the printing and packaging industries.

The choice of an industrial cutting blade depends on three fundamental factors: design, material, and coating. Thanks to our wide range of options, we help each customer choose the right blade to ensure maximum performance in their process.

European-quality industrial blades for superior results

Manufactured with European materials and under strict quality standards, our cutting blades offer:

Optimized thicknesses

Thinner blades require less force, reduce belt breakage, and provide a cleaner cut.

Adaptable designs

With rounded or square corners, slotted or triple holes, to adapt to different machines and cutting needs.

High-performance materials

Carbon steel, stainless steel, tool steel (HSS-M2, D2), tungsten carbide, or solid ceramic.

Specialized coatings

They extend service life, reduce friction, and improve cutting quality even in demanding applications.

Technical characteristics of the cutting blades

Thickness yield

Thinner blades require less force and offer a more precise cut. They also help prevent belt breakage and improve process efficiency.

Material performance

We offer industrial cutting blades in a wide variety of materials optimized for specific applications:

- Carbon steel

- Stainless steel

- Tool steel

- Steel HSS-M2

- Steel D2

- Tungsten carbide

- Solid ceramic

Coating performance

The coating on industrial blades extends their service life and improves cutting results. It also reduces friction, heat, and wear, optimizing productivity.

Types of coatings available

Gold coating that reduces friction, generates less dust, and ensures competitive performance. FDA approved.

Application: Plastic film and sheets with few additives.

K – Black ceramic

Very fine grain that protects the edge when cutting white films with a high chalk content. FDA approved.

Application: white films with additives.

Z – Zero friction

Low-friction gray coating, ideal for high-speed cutting. FDA and CE approved.

Application: thin stretch film.

X – Complete ceramics

Full coating, including the sides of the blade. Offers maximum durability when cutting highly abrasive materials. FDA and CE approved.

Application: Multilayer plastic films or films with aggressive additives.

C – Solid ceramic

Self-sharpening during use, high heat resistance, although more fragile when handled.

Application: soft flexible film (EBA).

V – Solid tungsten carbide

Maximum strength and durability, even when cutting very hard materials.

Application: rigid laminated films (PE) and plastic packaging.

Applications of industrial cutting blades

Our slitter blades are used on a wide variety of materials:

- Adhesive films

- Plastic films (printed or unprinted, with CaCO3, coated, aluminized, or laminated)

- Stretch and multilayer films

- Rigid laminates

- Post-consumer recycled plastics (PCR)

- Aluminum foil

- PVC

- PET, PE, PS, PA

- EBA

- PP, CPP, PC

- LDPE, LLDPE, HDPE

- BOPP, BOPE, BOPET

- Paper

- Textiles

- Other special materials

Advantages of our cutting blades

Precise and uniform cut

Prevents burrs, belt breakage, and defects in the final product.

Long service life

Durable materials and coatings that extend performance.

Increased productivity

Fewer stoppages due to wear and tear or replacement, faster processing.

Specialized technical support

Personalized advice to choose the right blade for each application.

Frequently asked questions about industrial cutting blades

What material is best suited for my cutting blade?

It depends on the material to be cut and the speed of the machine. Stainless steel is ideal for standard cuts, while tungsten carbide or ceramic are recommended for demanding applications and abrasive materials.

What advantages do coatings offer?

They reduce friction, extend service life, and improve cutting quality, especially in plastic films with additives or in high-speed processes.

Can I request custom blades?

Yes, we offer custom-made blades in different thicknesses, diameters, and coatings to suit each machine.

Do you offer custom scrapers?

Yes. We can supply custom-made scrapers to suit the exact specifications of your machine and process.

Are they compatible with any cutter or rewinder?

We offer standard and special models that cover virtually all brands and configurations of machinery on the market.