Washing machines for inks, anilox rolls, printing plates, machine parts.

Industrial washing machines for anilox rolls, printing plates, and printing components

At LMG Green, we offer a wide range of industrial washing machines designed specifically for the printing industry, capable of thoroughly and efficiently cleaning cylinders, plates, anilox rolls, ink trays, and other components used in flexographic, rotogravure, and offset printing processes.

Our washing systems combine advanced technology, high-quality materials, and complete automation, ensuring uniform, safe, and environmentally friendly cleaning.

Efficient and sustainable industrial washing

Each LMG Green washer is designed to optimize water and solvent consumption, reducing operating costs and environmental impact.

Thanks to its closed-loop system, washing fluids are reused in automatic cycles, preventing spills and improving operator safety.

Made of AISI 304 stainless steel, our washing machines offer a long service life, minimal maintenance, and compatibility with remote control systems (Industry 4.0).

Available models of industrial washing machines

Universal Washing Machine "VEGA"

Designed for cleaning general components in the graphics industry, VEGA guarantees thorough cleaning thanks to a system of self-rotating heads that cover the entire surface of the parts.

Key features:

Horizontal movement with four self-rotating double-nozzle heads.

Closed-loop, sealed fluid management.

100-liter conical tanks made of stainless steel.

Internal filtration using 500-micron filters.

Integrated control panel with pneumatic management.

Ideal for cleaning trays, decks, rollers, and general components.

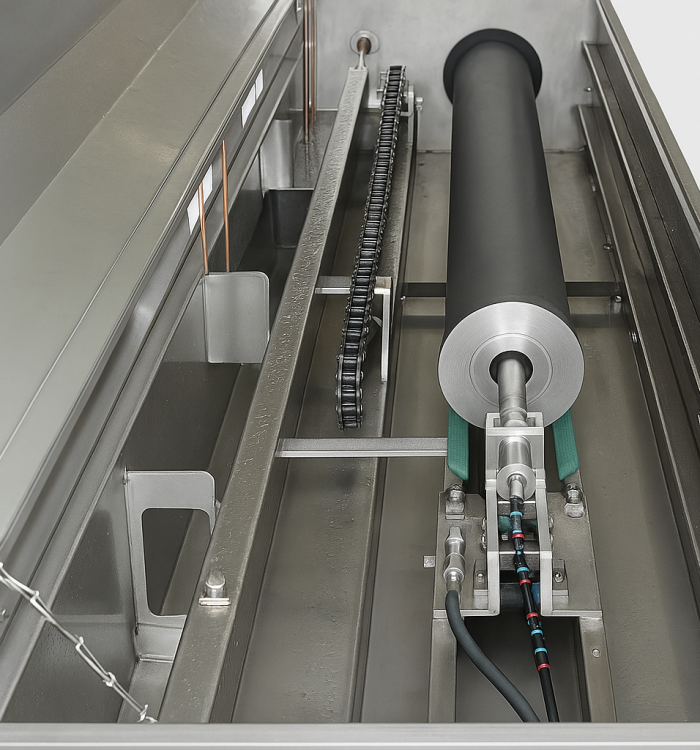

ORION cylinder washing machine

The ORION washer is specially designed for small cylinders, trays, and side components of printing presses.

It offers thorough and safe cleaning thanks to its adjustable horizontal movement and integrated safety systems.

Technical advantages:

Adjustable Teflon supports.

Washing and blowing nozzles on horizontal carriage.

Lid opening sensor and safety vacuum valve.

Internal filtration with 500-micron stainless steel filters.

100-liter tank with level control.

Made entirely of AISI 304 stainless steel for maximum durability.

PEGASO washing unit

PEGASO is a high-pressure washing unit for anilox rolls and sleeves, combining power, precision, and sustainability.

Features:

Washed with mains water at 120 bar and blown with compressed air.

50-liter stainless steel chemical tank with level sensor.

Adjustable spray bar and spray head.

Closed-loop chemical recirculation system.

Maximum chemical consumption: 1 l/min.

Made entirely of AISI 304 stainless steel, it guarantees thorough cleaning with low energy consumption.

SIRIUS ultrasonic washing machineLavadora ultrasónica “SIRIUS”

The SIRIUS unit uses 40 KHz ultrasonic technology for cleaning anilox rolls and sleeves, achieving impeccable results even in hard-to-reach areas.

Technical details:

Resin-coated piezoelectric transducers.

Motorized rotation of the anilox/sleeve.

Total operating power up to 6000 W.

Easy-to-maintain submersible modules.

Ideal for removing dried ink or encrusted residue without damaging the surface.

“ELECTRA” plate washing machine

ELECTRA is designed for flat photopolymer plates, offering fully automatic washing, rinsing, and drying.

Features:

Motorized rubber rollers and conveyor brushes.

Hot air rinsing and drying units.

Control panel with touch screen and PLC.

Removable wash and rinse tanks with drainage.

Washable cartridge filter.

Ensures a fast and safe process for plates between 1.14 mm and 3.5 mm.

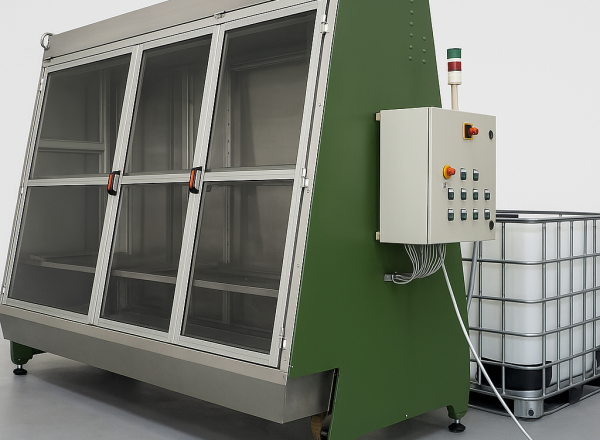

VELA washing machine for corrugated cardboard

Designed for large format clichés, VELA offers wide front access and visual control of the cycle.

Key benefits:

Transparent front sliding opening.

Two 500-liter PET tanks (washing and rinsing).

Removable washing trolley with blow nozzles.

Electrical panel with alarms and signaling column.

Ready for 4.0 connectivity.

Ideal for corrugated cardboard printers that require speed and reliability.Ideal para impresoras de cartón ondulado que requieren rapidez y fiabilidad.

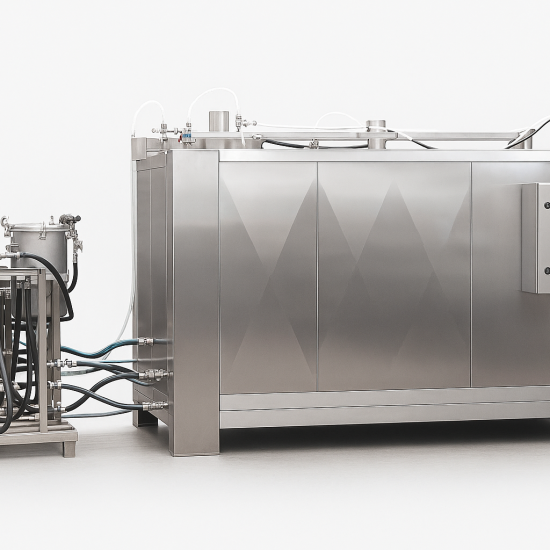

“LIBRA” car wash tunnel

The LIBRA tunnel washer is designed for rotary and flexographic printing press components.

It offers a complete washing, rinsing, and blowing cycle in just 30 minutes.

Features:

200-liter tanks with conical bottoms.

500-micron stainless steel filters.

Pneumatic panel with automatic functions.

Closed, sealed washing and rinsing circuit.

Safety opening sensor and vacuum valve.

Ideal solution for continuous operations and cleaning large parts.

Applications of LMG Green industrial washing machines

Our washing machines are used in various areas of the graphics and printing industry:

Flexography and rotogravure.

Offset and screen printing.

Manufacture of packaging and labels.

Cleaning of anilox rolls, printing plates, trays, and rollers.

Industrial maintenance processes.

Advantages of LMG Green washing machines

Thorough and uniform cleaning of all components.

Reduction in water and chemical consumption.

Automatic and closed-loop processes.

Safe and ergonomic design for the operator.

Sturdy stainless steel structure.

Compatibility 4.0 for remote control and diagnostics.

Compliance with European safety and environmental regulations.

Frequently asked questions about industrial washing machines

What type of washing machine do I need for my printing process?

It depends on the component to be cleaned. VEGA and ORION are ideal for general parts; SIRIUS and PEGASO for anilox rolls; ELECTRA and VELA for printing plates.

Can the water or solvent from the washing process be reused?

Yes, all LMG Green washing machines operate with recirculation and filtration systems, reducing consumption and waste.

Do they require a lot of maintenance?

No. The equipment is designed to minimize manual intervention and facilitate internal cleaning with removable filters.

Are they compatible with LMG Green water treatment systems or distillers?

Absolutely. They can be integrated to form a complete line of resource management and recovery.

Do they comply with industrial safety standards?

Yes. All models feature safety sensors, vacuum valves, and CE and ATEX certifications depending on the model.