Aufer is in a position to make software and hardware upgrades on all machines.

Currently, some companies can not guarantee the supply of spare parts, mostly electronic, the main reason among others is due to the discontinuity in the manufacture of that spare part by the machine producer, being discontinued or obsolete, this causes that when any of these parts fails, the machine remains damaged for a long period of time and the repair is usually quite expensive in all terms.

To find solutions, we have formed a team capable of developing softwares with Siemens (TIA Portal), and thus be able to perform upgrades and retrofitting, in this way the machine is extended its useful life, guaranteeing a minimum of a decade without problems of supply in their hardware and software, avoiding forced stoppages due to an obsolete or discontinued electronic replacement of difficult repair or replacement.

Advantages of an upgrade:

- Software and hardware updated.

- Open software, of which the client always has a copy, and generic components.

- New features in the software to improve and optimize the process.

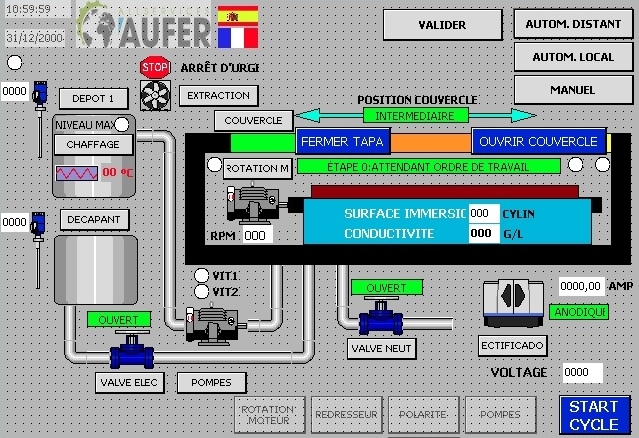

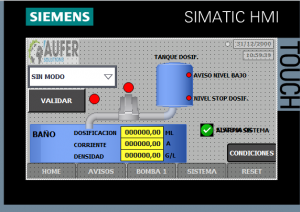

- Replacement of old keypads and analog controls by touch screens b/w or color, according to the customer's wishes.

- The PLC can be accessed through an Ethernet connection with which remote assistance is possible.

- Possibility of a larger screen, details, graphics and custom improvements in the software to suit the client.

- We use the same operational logic, that is, it does not require a large training of the operators, because the operation of the machine remains identical, except for improvements and details requested by the client.

- Much of the non-obsolete hardware can be integrated.

- Possibility of doing it in any language.

For reference you can see below the details of some of the latest projects, which can be visited without commitment:

New software and hardware in Duostar machine. (Lamigraf).

New software and hardware in copper bath. (Amcor Turkey).

New software and hardware in degreasing tank(Burda).

New software and hardware in a combined degreasing and dechroming tank (Impress).

Chrome tank software optimization. (Alinvest Czech Republic).

Automatic dosage of chemicals for automatic line. (Spain)

UPGRADE "INDUSTRY 4.0"

With our knowledge and a small investment in Siemens software and hardware, we can collect data from any part of your company to collect them and create production control tools, obtain consumption control, personnel performance, remote power off / on, or any value or resource that the clustomer wants to have under their control without the need to fill out control books or tedious spreadsheets, there is also the possibility of seeing these values exclusively on their mobile device or from outside the company.